Transformer sales and Rental Services

Smart & IoT-Enabled Transformers:

- 1.The provided Transformers will come with embedded sensors and connectivityfor real-time monitoring of temperature, load, fault conditions, and oil quality.

- This enables predictive maintenance, reducing downtime and extendingtransformer lifespans.

Eco-Friendly & Energy-Efficient Designs:

- Rental and sale fleets increasingly include dry-type and low-loss core

transformers, meeting stricter energy efficiency and emission standards. - We offer biodegradable insulating fluids and amorphous metal cores for

reduced environmental impact and improved performance

Modular, Skid & Containerized Units:

- To support fast deployment and flexibility, transformers are offered in modular

skid-mounted or containerized formats, including medium- and high-voltageoptions. - Ideal for emergencies, site commissioning, and renewable energy applications.

Right-Sized Fleet for Sales & Rental:

- We maintain a wide range of units, from 300 kVA to 7 MVA, with varyingvoltageclasses (e.g., from 2.4 kV to 34.5 kV).

- Offers include pad-mounted, dry-type, and oil-filled units suited to industrial, utility, and construction needs.

Advanced Engineering & Integration Support:

- We offer comprehensive services: site assessments, system-level electrical

distribution design, load-flow analysis, plus SCADA/systemintegrationfor

smart grid compatibility.

Rental-Specific Features:

- Quick shipping, forklift pockets, and remote monitoring platforms for rapiddeployment during outages or planned projects.

- Flexible rental terms—short- to long-term—with turnkey delivery and pickupservices.

Digital Twins & Analytics:

- We deploy digital twin models for simulation, diagnostics, and performanceanalytics.

- Allows operators to simulate grid behavior and predict faults, optimizingmaintenance cycles and costs.

We are evolving to offer digitally smart, sustainable, and modular transformer

solutions. Our services include full engineering support, flexible logistics, real-timemonitoring, and digital analytics—meeting the demands of modern power infrastructure

Low voltage power generation, distribution, protection, sales and rental

Temporary & Permanent LV Power Systems:

- Portable transformer substations, distribution panels, LV switchgear (up

to 600 V), batteries, transfer switches, cables, and VFDs for both onsiteinstallations and long-term setups.

Turnkey Rental & Sales Bundles:

- Services include generator + transformer + switchgear + ATS + cables. Often provided as full EPC or plug and play kits for construction sites, events, utilities, and industrial clients. o

- Rental includes installation, commissioning, maintenance, and onsitesupport (24/7).

Protection & Switchgear:

- Low-voltage switchgear systems with circuit breakers, VFDs, starters, arc- resistant cabinets, interlocking, and bus protection.

- LV protection via protective relays, overcurrent/fault detection, andtransfer switch automation.

Design, Commissioning & Integration:

- Project planning includes load calculations, cable sizing, short circuit

analysis, power factor correction, and grounding systems. - Commissioning services: testing, thermographic imaging, complianceverification (UL, IEEE, IEC standards).

Fleet Management & Digitalizing Assets:

- Inventory tracked (e.g., barcoded LV cables), managed with digital

systems. Rental fleets include portable transformer substations, LVswitchboards, cables, and ATS. - Integration with SCADA/DCS platforms for monitoring, control, andenergymanagement.

Support Services & Safety Compliance:

- Neolatec skilled engineer-led teams handle transportation, installation, preventative maintenance, troubleshooting, inventory logistics, andspareparts management.

- Compliance with relevant electrical codes, arc-flash safety, and buildingregulations.

Industrial Instrumentation, cabinets and panel termination in oil and gas industries

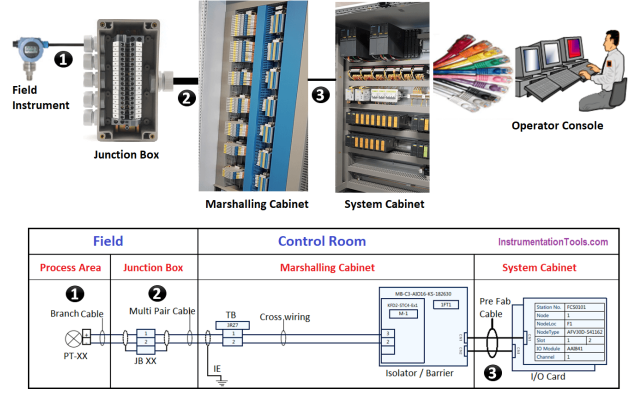

Marshalling & System Cabinets:

- Marshalling cabinets for systematic termination of field instrument cables, surgeprotection, IS barriers, and organized cross-wiring to I/O modules.

- System cum marshalling cabinets combine both marshalling and control

hardware when I/O density is moderate 2. Termination & Junction Boxes. - Field junction boxes minimize long cable runs; they consolidate and protect

wiring at safe locations before marshalling. - Use of cable entry systems (glands/strain-relief) ensures IP-rated protectionandcontrolled routing into cabinets

Control & RTU/PLC Panels:

- RTU/PLC control cabinets for automation and SCADA, often skid-mountedand

built to withstand hazardous environments (e.g., H2S, salt spray) with stainlesssteel enclosures. - Includes remote data acquisition, ESD functions, and often solar backupinupstream applications.

Hazardous Area Certification & Robust Construction:

- Enclosures are ATEX/IECEx/NEMA/IP rated, stainless or coated, explosion-proof, and suitable for corrosive offshore or field use

Electromechanical Panel

Integration:

- In-house panel fabrication facilities design and assemble marshalling units, RTUracks, VFD/MCC panels, and ATEX panels per IEC/IECEx standards.

Wiring, Labelling & Testing Protocols:

- Systems employ structured cable ladders, tagged terminal blocks, and rigorousloop checking and wiring verification.

- FAT/SAT (factory/site acceptance tests) ensure wire termination integrity and performance.

Lifecycle Support:

- Full lifecycle services: design, procurement, FAT, commissioning, calibration, preventive maintenance, and troubleshooting.

- Field teams install and support panels on location, performcalibration andre- certification as needed.

Industrial and local Inverter and Solar System.

Diverse Inverter Types:

- From central inverters (for large industrial rooftops and ground-mountedarrays) to string, hybrid, and micro inverters (used in local and residential

setups).

Maximum Power Point Tracking (MPPT):

- Multi-MPPT technology in string/hybrid inverters maximizes energy

harvest, especially under shading or varied panel conditions

Hybrid & Bi Directional Capability:

- Inverters that seamlessly switch between solar generation, battery storage, and grid power—managing charging/discharging and backup needs

Smart Grid Support & Compliance:

- Advanced inverters offer voltage/frequency regulation, anti islandingprotection, and adhere to global grid codes like IEEE 1547 and UL1741SA

High Efficiency & Thermal Management:

- State of the art designs (>98 % efficiency) plus cooling methods (air- cooled cabinets, IGBT heat control) for high reliability and minimal losses

Remote Monitoring & Digital Integration:

- Cloud platforms offer performance dashboards, fault alerts, firmwareupdates, and string/panel-level insights via smart communication

Comprehensive Engineering & Turn key Solutions:

- From site assessment and electrical permitting (PV plan sets) toinstallation, commissioning, and O&M, including energy storage

integration

Balance of System (BOS) Integration:

- Expertise in racking, combiner boxes, metering, wiring, monitoring, andaccessories ensure seamless system performance

Industrial Civil works

Heavy Civil Construction & Earthworks:

- Large-scale site prep: mass earthmoving, grading (rough and fine), cut-and-fill operations for infrastructure projects

- Advanced management of erosion, drainage, and stormwater systemsintegrated into construction plans

Civil Infrastructure:

- Building public works: highways, bridges, railways, airport facilities, canals, dams, reservoirs, and wastewater treatment plants

- Contractors often certified for earthquake/structural loading, chemical- resistant installations, bulk fuel storage support, and plant service buildings

Industrial Facility Development:

- Construction of factories, warehouses, fuel and material handlingstructures, effluent systems, workshops, control rooms, and adminbuildings.

- Turnkey engineering, procurement, and construction (EPC) services, oftencombined with process, mechanical, and environmental engineeringdisciplines.

Foundations & Specialized Structures:

- Design and execution of foundation systems, subgrade compaction, andstructural steel/concrete works tuned for industrial loads

Project Management & Digital Collaboration:

- Use of BIM, site analytics, safety planning, quality monitoring, andagileproject oversight from pre-construction through close out

Safety, Compliance & Sustainability:

- Strict adherence to ISO, OSHA, environmental, and structural standards, with safety audits and training embedded in project culture

- Focused attention on erosion control, sustainable materials, green-sitedesign, and stormwater mitigation

Supply Chain & Fabrication:

- Integrated shop fabrication of metal components, coatings, precast elements, on-site welding, pipe and pressure vessel installation.

Industrial Mechanical works

Piping & Process Equipment Design:

- Detailed engineering, stress analysis (e.g., CAESAR II), hydraulic modeling, and layout for plant piping systems—covering chemicals, steam, gas, compressed air, and process fluids

- Integration with pumps, compressors, heat exchangers, and other rotatingequipment in centralized plants or industrial facilities

HVAC, Utilities & Central Plants:

- Industrial HVAC systems: chilled/hot water, cooling towers, ductwork, fan

walls, variable-speed drives, and energy optimization

3D Modeling & BIM Delivery:

- Use of advanced CAD/BIM tools to coordinate spatial layouts, crossdiscipline clashes, and equipment clearances. Feasibility and

constructability reviews are integral.

Design-to-Construction Lifecycle:

- Services cover conceptual/FEED design, detailed engineering, procurement support, shop fabrication, installation supervision, andcommissioning.

- On-site commissioning includes performance testing, loop checks, fluencywith FAR/FS, and quality control.

Process Systems & Rotating Equipment:

- Engineering of compressors, turbines, pumps, mixers, and skids, oftenwithin process, chemical, and power-generation plants

- Enabling front-end studies, HAZOP reviews, process optimization, andperformance modeling.

Energy & Sustainability Optimization:

- Energy-efficiency through system analysis, heat recovery, LEED/sustainability compliance, and system audits.

Safety, Standards & Quality Assurance:

- Strict adherence to ASME, ANSI, ASTM, NFPA, ISO standards. Processeslike loop checking, FAT/SAT, weld inspection, and QA/QC are standard procedures.

Industrial QA and QC works

Structured QA/QC Management Systems:

- We implement Quality Management Systems (QMS) aligned with standardslikeISO 9001, ASME, API, and AWS. They create and enforce Quality Plans,

Inspection & Test Plans (ITPs), and Non-Conformance Reports (NCRs) - We often oversee coordination between manufacturers, contractors, andclientsto ensure compliance from procurement to installation.

NDT & Inspection Expertise:

- Offer a broad range of non-destructive testing (NDT): radiography, ultrasonic, magnetic particle, liquid dye-penetrant, alloy verification, hardness testing, andcoating inspections

- Provide certified inspectors (e.g., CWI, NDT Level II/III) across industries likeoil &gas, petrochemical, power, and infrastructure.

Factory & Site Acceptance Testing (FAT/SAT):

- Conduct FAT/SAT inspections to verify equipment compliance, correct

installation, testing, and calibration before handover. - QA/QC engineers ensure documentation, sequence protocols, and

commissioning checks are accurate.

On-Site Quality Auditing & Process Control:

- Perform routine site inspections, dimensional checks, welding inspections, andsteel fabrication audits.

- Use QA oversight to detect defects, root-cause failure analysis, and implement

corrective measures across supply chains.

Supplier Expediting & Vendor Management:

- Engineering of compressors, turbines, pumps, mixers, and skids, oftenwithin process, chemical, and power-generation plants

- Enabling front-end studies, HAZOP reviews, process optimization, andperformance modeling.

Advanced QA/QC Technologies:

- Integrate automated inspection (e.g., vision systems, sensors), industrial IoT for

real-time data, robotics, and analytics to increase inspection consistency - Use data-driven dashboards for tracking quality KPIs and continuous

improvement.

Compliance, Safety & Certification Support:

- Ensure adherence to national and industry codes (ISO, ASME, API, AWS). Provide

welding compliance (CWI), radiographic interpretation, and internal/external

audits. - Integrate safety into Quality (“SAFE & quality first”) and support certificationaudits like API, ISO, or regulatory body requirements.

Industrial projects management

Neolatec industrial project management exhibit core capabilities designed todeliver

complex projects on time, within budget, and to exacting standards.

Robust Organizational Structure:

- Multi-disciplinary teams: Project managers, engineers (civil, mechanical, electrical), procurement, quality/safety, finance, and site lead work in tandem

- Clear role definition—from C-suite oversight to on-site supervisors—ensuresaccountability and streamlined communication Use of Gantt charts, Critical PathMethod (CPM

Planning & Scheduling Expertise:

- Hybrid Agile-Waterfall approaches to manage timelines and dependencies.

- Phased planning aligns engineering, procurement, construction, and

commissioning seamlessly.

Cost & Resource Control:

- Integrated budget tracking, time recording, and resource allocation tools tiefinancials directly to project progress

- Regular financial reviews and forecast adjustments prevent overruns.

Risk & Quality Management:

- Comprehensive risk registers and mitigation plans for technical, safety, andsupply-chain issues.

- QA/QC protocols embedded into workflows using loop checks, FAT/SATs, andnon-conformance tracking.

Digital Tools & BIM Integration:

- Use of BIM provides clash detection, construction visualization, and lifecycledata access

- Cloud-based platforms (e.g., Smartsheet, MS Project, Plan Radar) centralizedocumentation, communication, and updates.

Stakeholder & Communication Systems:

- Defined communication plans: regular updates (daily/weekly), dashboards, andstakeholder reporting.

- Emphasis on transparency and early-warning systems to surface issues beforethey escalate.

Collaborative Delivery Models:

- Adoption of Integrated Project Delivery (IPD) and Lean construction

methodologies to align engineering, suppliers, and contractors early in theproject lifecycle - Focus on waste reduction, continuous improvement, and value-driven outcomes.

Strong Safety & Compliance Framework:

- Safety planning, personal protective measures, and compliance with

ISO/OSHA/industry codes are non-negotiable. - Routine inspections and audits ensure ongoing adherence to standards.

Continuous Improvement and Analytics:

- Use of dashboards, KPIs, and analytics to identify trends, improve processes, andcapture lessons learned.

- AI-driven forecasting and automation enhance decision-making and resourceefficiency.

Risk & Quality Management:

- Comprehensive risk registers and mitigation plans for technical, safety, andsupply-chain issues.

- QA/QC protocols embedded into workflows using loop checks, FAT/SATs, andnon-conformance tracking.

Digital Tools & BIM Integration:

- Use of BIM provides clash detection, construction visualization, and lifecycledata access

- Cloud-based platforms (e.g., Smartsheet, MS Project, Plan Radar) centralizedocumentation, communication, and updates

Stakeholder & Communication Systems:

- Defined communication plans: regular updates (daily/weekly), dashboards, andstakeholder reporting.

- Emphasis on transparency and early-warning systems to surface issues beforethey escalate.

Collaborative Delivery Models:

- Adoption of Integrated Project Delivery (IPD) and Lean construction

methodologies to align engineering, suppliers, and contractors early in theproject lifecycle - Focus on waste reduction, continuous improvement, and value-driven outcomes.

Strong Safety & Compliance Framework:

- Safety planning, personal protective measures, and compliance with

ISO/OSHA/industry codes are non-negotiable. - Routine inspections and audits ensure ongoing adherence to standards.

Continuous Improvement and Analytics:

- Use of dashboards, KPIs, and analytics to identify trends, improve processes, andcapture lessons learned

- AI-driven forecasting and automation enhance decision-making and resourceefficiency.